Spectrum Plastics Group and Laser Light Technologies Collaboration

Spectrum Plastics Group and Laser Light Technologies Collaboration

ALPHARETTA, GA (June 24, 2020)—Spectrum Plastics Group, a global developer, manufacturer and supplier of medical device components, sub-assemblies, and full-service solutions, is announcing a strategic partnership with Laser Light Technologies.

The collaboration will provide quick-turn, “off-the-shelf” extruded tubing with high-precision laser-cut features, available for next-day delivery in North America and within three days for international destinations.

Spectrum Plastics Group, the largest independent extruder of conventional and advanced medical tubing in North America, selected Laser Light Technologies to help expand and extend its product offerings for new catheter and medical device applications that require tubing and sub-assembly.

These new products will focus on drug delivery, a specialty of Laser Light Technologies, irrigation and infusion, and add to Spectrum Plastics Group’s off-the-shelf offerings for medical device manufacturers and other end users, including its Apollo® thin-walled, high-performance, and tight-tolerance catheters for applications such as blood and fluid management, vascular access, cardiology, and robotic surgery.

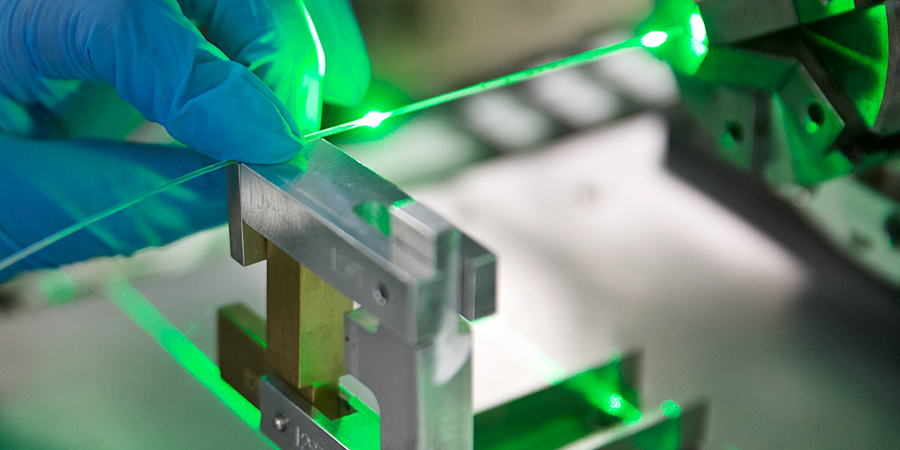

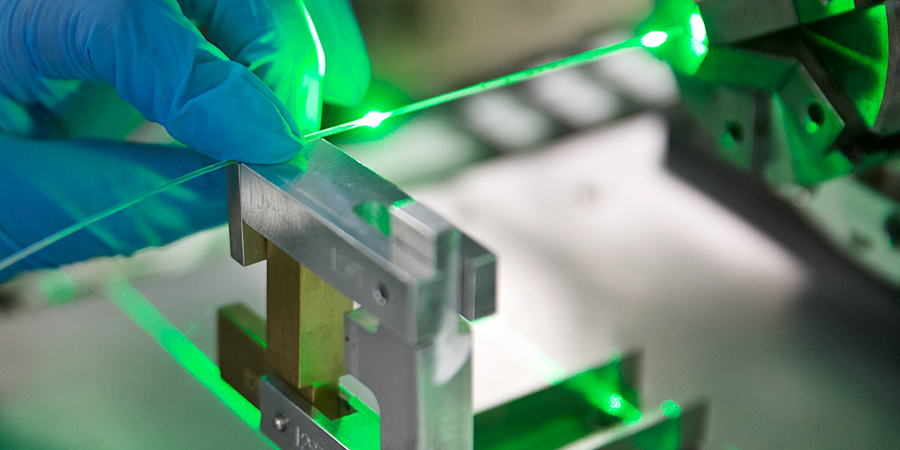

One of Laser Light’s strengths is finding innovative ways to make challenging designs possible with laser machining. “Spectrum Plastics Group is a leader in medical tubing manufacturing and Laser Light Technologies is an expert at the laser manufacturing of high-precision products,” said Laser Light CEO Frank Hannan. “This strategic partnership allows us to combine our respective strengths and develop innovative, high-value medical products that enhance medical procedures and improve patient outcomes.”

Combining Apollo® extrusions with Laser Light’s precision laser manufacturing technologies (features as small as a single micron) will provide an additional value-added step that saves customers time and effort when they are conceptualizing innovative new products.

The new product offerings, consisting of a variety of 4Fr-12 Fr Pebax® 55D and Nylon 12 extrusions with laser-cut hole configurations for a variety of drug-delivery and other medical applications, will launch via Spectrum Plastics Group’s web store (webstore.spectrumplastics.com).

“Our online store accelerates the design and development of medical device projects by providing over 650 purposely designed single-lumen, multi-lumen, and reinforced tubes in stock that can be delivered within 24 hours,” said Mike Schultz, vice president of Innovation and Development at Spectrum Plastics. “The partnership with Laser Light allows us to increase our extrusion offerings and add a new product category that delivers valued-added capabilities.”

About Spectrum Plastics Group

Based in Alpharetta, Georgia with multiple plants across the United States, Mexico, Costa Rica, Ireland and Malaysia, Spectrum Plastics Group is a North American leader in the design and fabrication of custom and specialty plastics products focusing on niche, high value-added end markets, including medical, food and defense applications. Spectrum Plastics offers a full range of custom design, engineering and fabrication services, as well as meet the requirements of ISO 9001, ISO 13485, and operates multiple Class 7 and Class 8 clean rooms. For more information, visit www.spgindustries.com, www.spectrumplastics.com or call 404-564-8560.

About Laser Light Technologies

Laser Light Technologies, based in Hermann, Missouri, is an expert in the laser manufacturing of high-precision products. Design teams use a variety of high-tech laser systems to provide a wide range of high-precision micromachining services, including laser cutting and drilling, laser ablation and coating removal, and wire stripping. For more information, visit https://laserlight.com or call 888-648-5704.