Micromolding

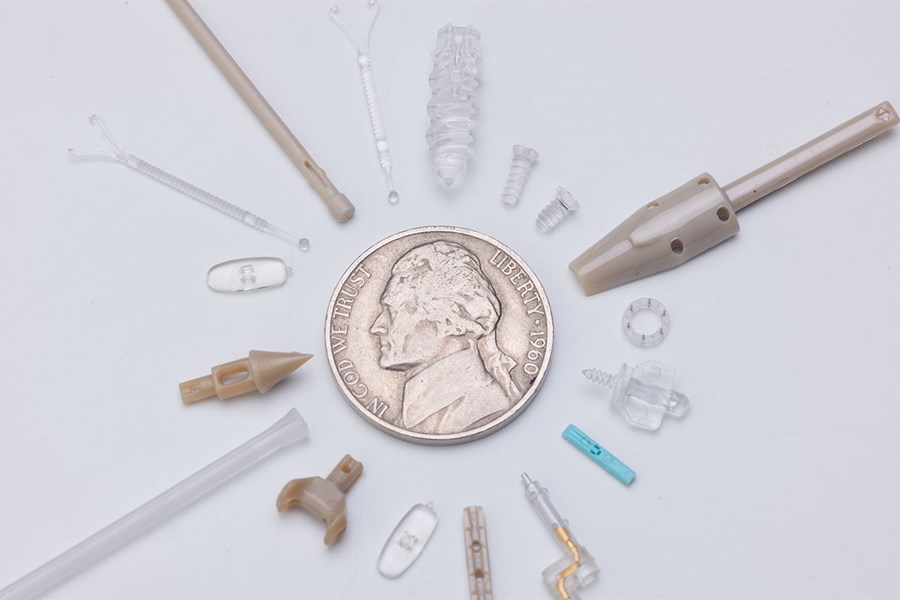

As medical treatments become less invasive, medical devices are getting smaller. We have the expertise to do precision micromolding, including specialized equipment, tool designs, and measurement systems.

Micromolding produces parts that weigh a fraction of a gram or as small as a single pellet. We understand the micromolding process, from raw material through QA inspection.

Capabilities

Successfully controlling the manufacturing of very small plastic parts or very small/precise features is not just regular molding on a small scale; it deals with microns, ensuring accuracy down to +/—1.5 microns and validating tiny components.

The future of micro injection molding technology is promising. With the continued development and improvement of building methods and designs for micro-tooling, the micromolding process and machines will keep advancing. The market for small and precise plastic parts is growing, and the future is bright.

All plastic resin materials used in traditional injection molding, including thermoplastic resins that are unfilled or highly filled, natural or colored, bioresorbables, fluoropolymers, and long-term implantable and liquid silicone rubber (LSR), work for micromolding.

Yes. We have the specialized equipment and the capacity to produce parts in small to large quantities, as our customers require. Our processes have been refined to be infinitely scalable.