Design & Development

We offer the full range of design, prototyping, and development services. We turn your device concept into a manufacturable design, transfer it to initial production, then manage full-scale production.

Design & Development

We offer the full range of design, prototyping, and development services. We turn your device concept into a manufacturable design, transfer it to initial production, then manage full-scale production.

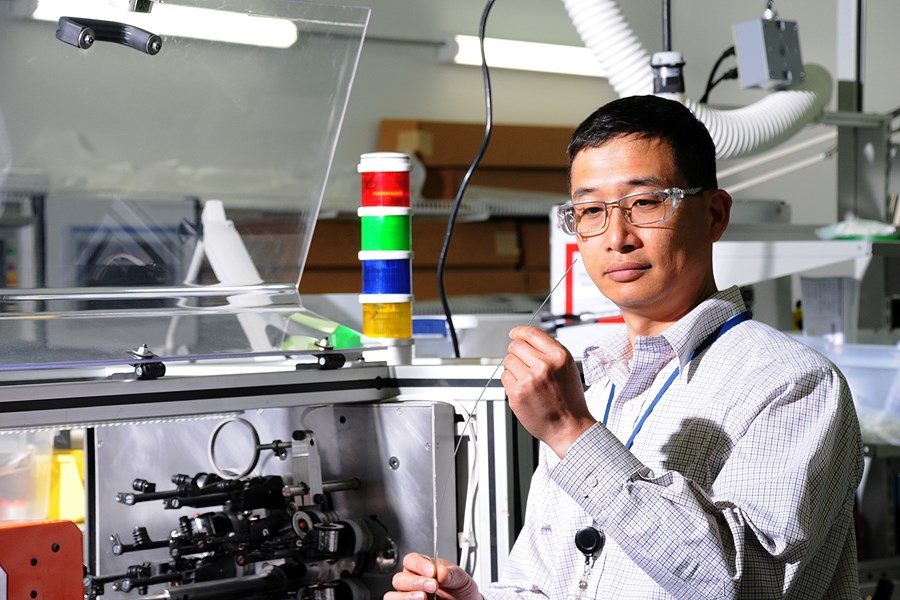

We are an FDA-registered manufacturer with 60+ years of manufacturing experience across a range of demanding markets. Our highly skilled, in-house technical team works closely with you from start to finish.

Our tooling capabilities feature extensive, advanced wire EDM and CNC technology, coupled with a highly trained technical workforce.

At Spectrum, we created Launch Pad, a powerful tool to propel your medical device design project to new heights. Launch Pad is a focused brainstorming session, providing participants with a collaborative experience with our team of technical experts. Bring us your idea and we’ll generate concepts and recommendations to help make it a reality. The Spectrum team is ready with the best medical device engineers and technologies to guide your project from launchpad into orbit.

Our expertise covers a spectrum of specialties including polymer science, device design, processes, manufacturing, and clinical applications.

Learn more about Launch Pad

The extrusion hub focuses on developing complex profiles and innovative extrusion processes to produce the components necessary to build next-generation devices, furthering the medical device industry. As part of this hub, we offer Engineering Days that enable engineers to work on our Sandy, Utah extrusion floor alongside our extrusion team. Engineers appreciate getting results in days instead of weeks, accelerating their project development and helping them make informed decisions.

Other Benefits of Engineering Days:

We offer more than other medical device companies in the industry when it comes to extrusion and catheters, taking your project from prototype to production in the shortest time possible.

Contact us for more information about our Engineering Days.