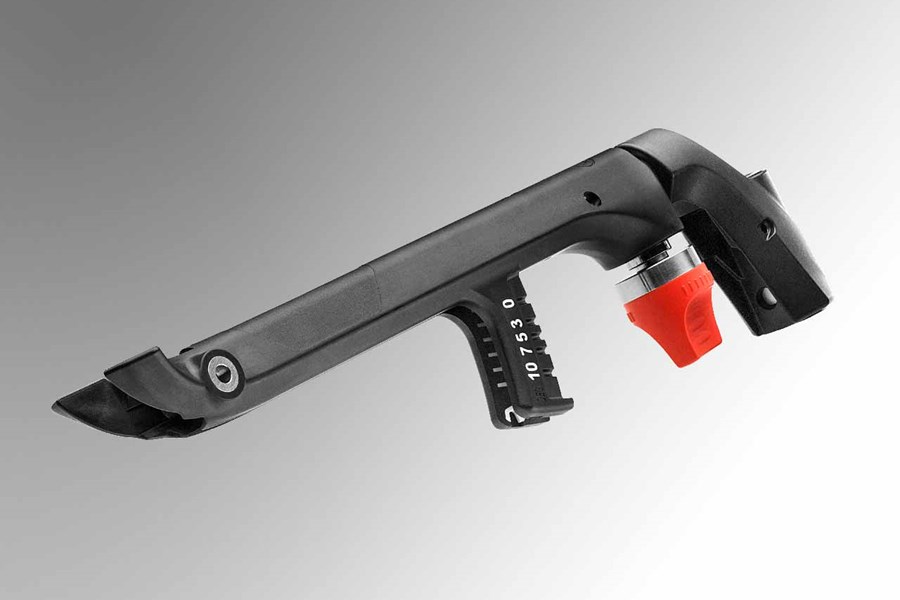

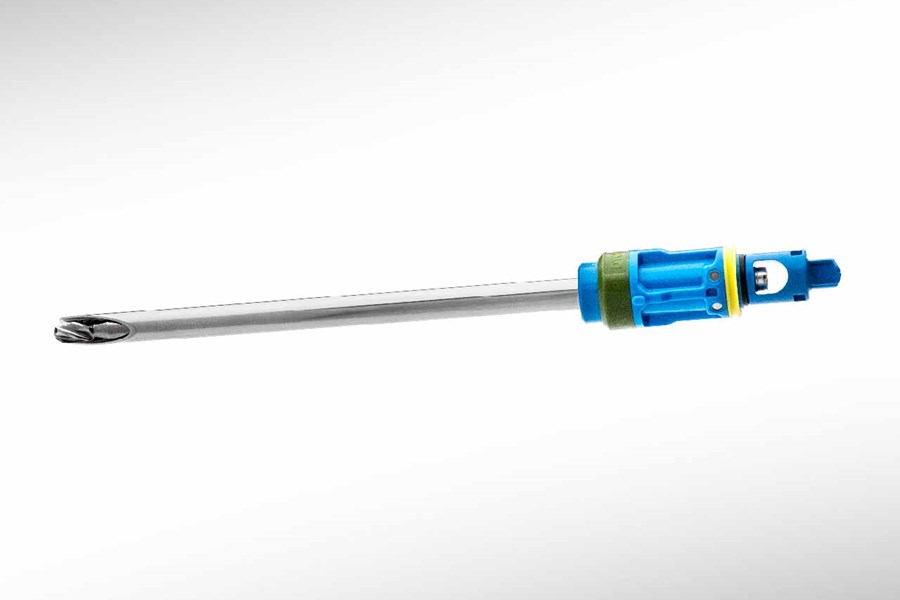

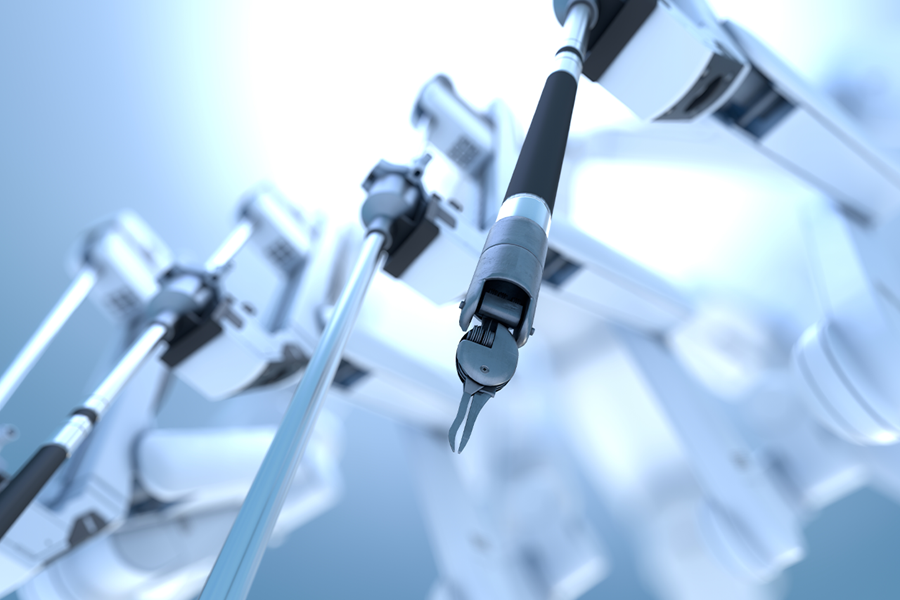

Overmolding & Insert Molding

We have decades of experience molding onto metal and other substrates. Combining properties of different materials, such as strength and flexibility, can create more intricate designs for aesthetics, branding, or ergonomics.