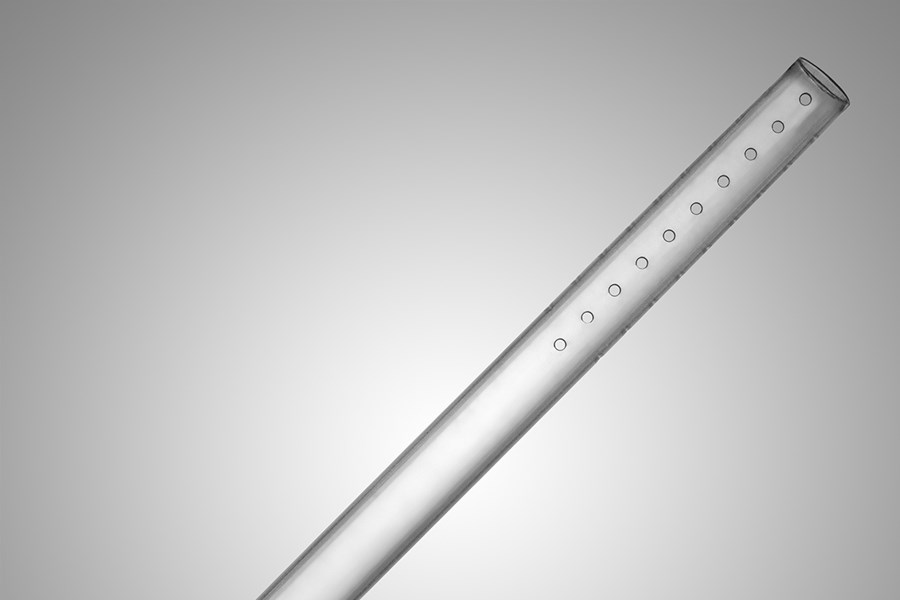

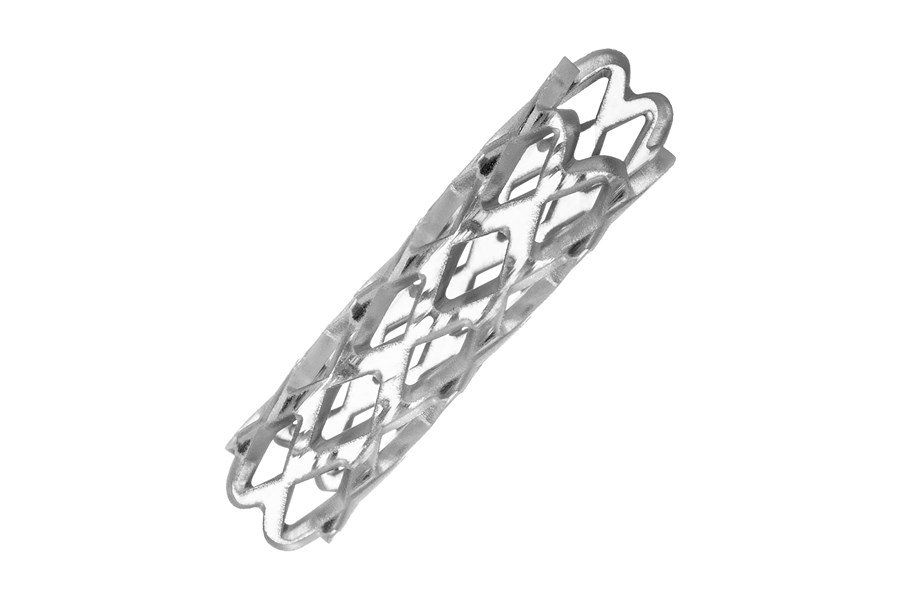

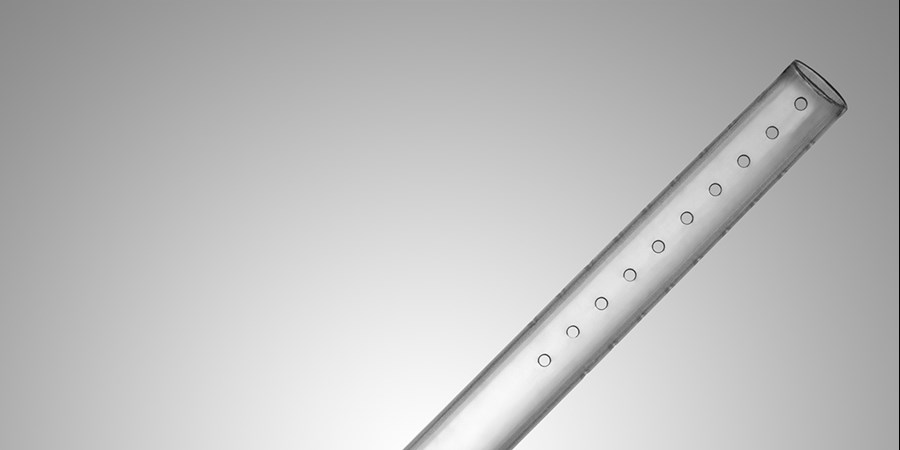

One of the greatest benefits of ultrafast lasers is the reliability and repeatability of the cutting of complex features and patterns, with great accuracy. Features can be as small as a few microns. The lack of burring or redeposited debris reduces or eliminates most post-processing, which saves time and reduces costs. Because they do not generate heat, lasers are ideal for cutting thin films and delicate materials. Laser-cutting systems can be operated unattended 24/7, thereby optimizing workflow and reducing operating costs.

Whether you need assistance cutting delicate parts to size, creating smoother edges, or cutting intricate shapes and patterns, Spectrum Plastics Group has the technology and experience to develop the best (and most cost-effective) laser-cutting process for your project.