Laser Tipping

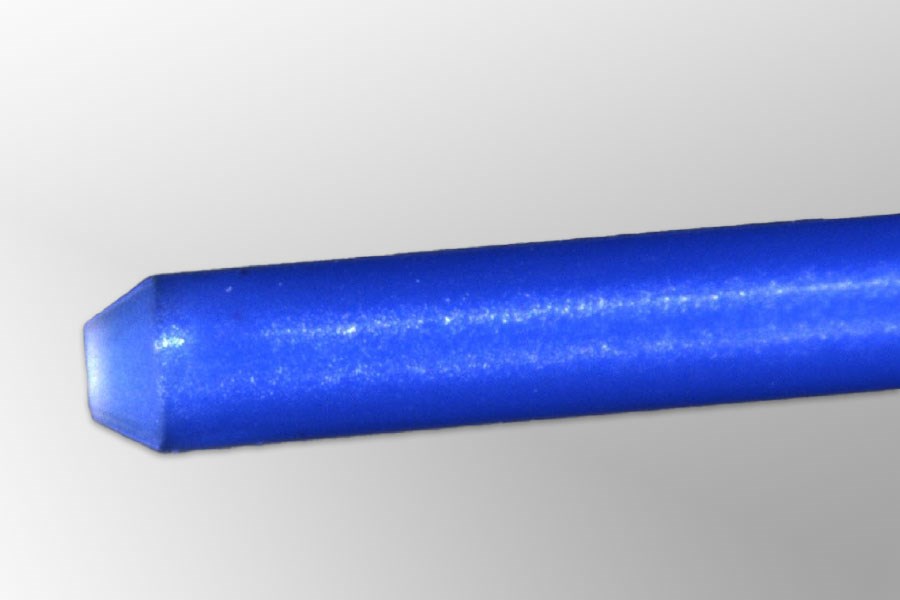

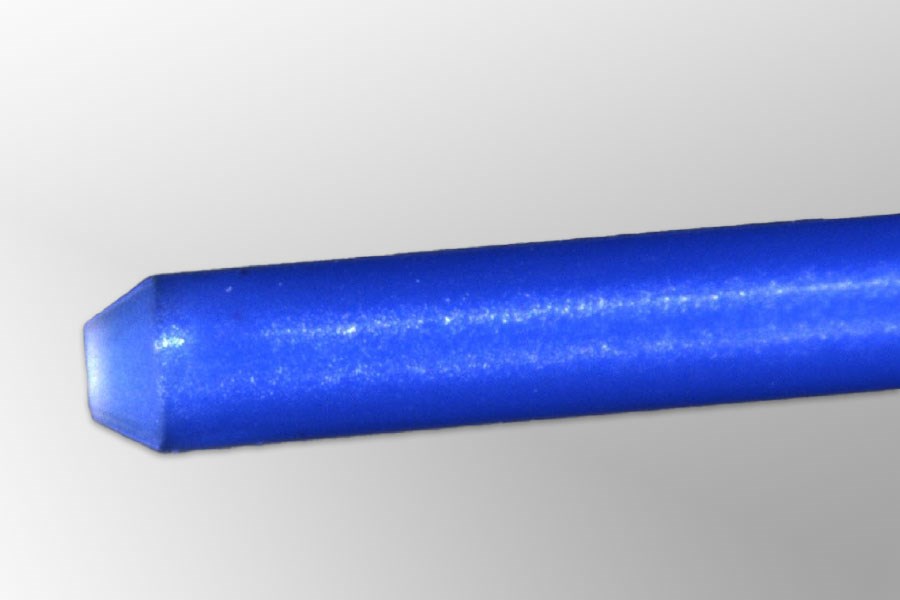

Tip-forming is the process of shaping the end of the catheter into a specific shape that enhances maneuverability. Spectrum engineers use a laser to form the tip; no heating and shaping is required.

Laser Tipping

Tip-forming is the process of shaping the end of the catheter into a specific shape that enhances maneuverability. Spectrum engineers use a laser to form the tip; no heating and shaping is required.

Medical catheters are thin plastic tubes that are inserted into a patient's body to support a variety of medical procedures, including diagnostic or exploratory evaluations, surgical procedures, and drug delivery. Depending on the procedure, each catheter requires a specific type of tip on the distal end. The shape of the tip is important for the ease of navigation during the procedure. Dimensions, materials, features, hardness, and lubricity are other key properties that must be considered for the catheter tip.

The standard approach for tip-forming uses heat and a specialized molding tool to shape the end of the catheter. Spectrum can offer a laser based alternative when the traditional tipping approach falls short.

Spectrum engineers use a laser to form the tip; no heating and shaping is required. Instead, the laser removes exactly the right amount of material to form the tip. Laser tipping can also be used to essentially skive or drill features into the tip that the other tipping methods cannot achieve. This means that we can make much more complicated and functional tips, faster, than the standard tipping methods.

Laser tipping also expands the range of materials that can be used for the catheter. When using heat, the catheter material must be able to withstand the heat required to shape the tip. This narrows the choices, where polyurethane or silicone are the most popular. which are both flexible and durable. Because laser tipping is a cold ablation process that does not impart heat into the material, there are no concerns about the heat tolerance of the material selected.

The catheter-tipping process can be customized to meet performance specifics for being part of a device or a specific application or procedure.

Benefits of laser tipping over other tip-forming methods include:

Depending on application, catheter tips may require specialized materials, such as radiopaque materials or polymer-fused marker bands. Other marker bands can be made from metals such as gold, tungsten, and platinum.

Tip geometries may include open or closed ends, irregular shapes, and even lumen-specific tips. Custom tips can include tapered inner diameters and/or outer diameters, specific wall thicknesses, and laser-drilled hole patterns and other features. Other options are rounded or low-profile ends and PTFE liners, in multiple configurations, depending on the procedure.

When considering how to design a tip, biomedical engineers must fully understand the medical procedure and how the catheter will be used. Tipped catheters are used in a growing number of minimally invasive surgeries, including cardiovascular, neurovascular, spinal, urological, gastrointestinal, and ophthalmic. Different surgical procedures require different tips—for example, a catheter used for cardiac procedures will have a different tip shape than one used for urological procedures. The structure of the tip is designed for ease and safety of insertion and smooth navigation through the anatomy.

Tip forming is a crucial aspect of medical catheter manufacturing. The process requires high precision and expertise to ensure that the final shape meets all dimensional and performance specifications and tolerances. SPG’s design teams collaborate with customer engineers to create the best catheter/tip solution for the specific application for which the catheter will be used, enhancing the surgical experience and improving patient outcomes.