Key Considerations When Selecting a Medical Injection Molder

Key Considerations When Selecting a Medical Injection Molder

Top 5 Things to Consider When Selecting a Medical Injection Molder

The North American injection molding industry has passed through a number of challenges and changes in the last decade and a half. Obviously, as across the entire Plastics Industry landscape much less all of North American manufacturing, the 2008/2009 financial crisis period played a – if not the most – dramatic role in shaping the profile of the industry today. As a simple example, in 2007-2008, the high point of the pre-crisis bubble, there were probably as many as 8,000 injection molders in North America. Within two years that population would reduce to just over 6,500.

Automotive is an instructive example here. In fact, when considering end-use applications for injection molders and a specific industry causing substantial supplier attrition, the automotive market is probably the most well-known instance. The sector limped along via easy-money monetary policies and credit following the late 1990’s peak vehicle production boom and through the 2000s. It culminated with the financial crisis in a hard rationalization of the supply base and overall industry structure.

Related indirectly to the trends causing the financial crisis, another significant challenge for plastics as with all U.S. industry has been the globalized shift in manufacturing to low-cost producing nations, namely China, as well as the impact this trade and economic momentum caused to specific industries. Electronics and telecom are notable industry examples here. In the 1990s and even early 2000s, both industries were reasonably profitable sectors for many plastic processors, including injection molding.

By the late 1990s, however, when China joined the WTO and was granted by the U.S. Congress Most Favored Nation trading status, a dynamic was set in motion whereby most electronics and telecom manufacturing found its way overseas and the domestic supply base to these industries changed quickly, undercutting most U.S. and even North American plastic manufacturers who had been supporting the industry base.

So it was in this context during the 2000s that a number of medium–sized injection molders, even some large ones too, strategically decided to shift their focus from industrial markets to other more promising sectors. Essentially, many of them went Medical.

Gone Medical. And why wouldn’t they? We’ve all heard the news about the demographic drivers, the ageing population, surging demand for healthcare benefits and insurance, the shift to consumer medical care, minimally invasive out-patient surgeries, etc., etc., etc. To paraphrase, maybe too accurately, a remark made infamous in another more challenging context, medical was/is a “slam dunk” for these plastics manufacturers.

But was it? For them, and/or for their customers? As a market and considering the macro indicators, surely a good case is made that it is. How about from another angle – was it so easy to convert an industrial plastics business to medical, with all the nuances, regulation, application complexity, institutional knowledge, and even its own vernacular, the language of medical?

The reality is no, and to an OEM looking for a solid plastics supplier and partner, there is a clear distinction in the industry between “New Medical” and those who have “Been Medical” for years.

In order to illuminate this distinction more clearly, Spectrum presents its Top 5 Criteria to Consider When Selecting a Medical Injection Molder:

Let’s take a quick look at each of these criteria.

Understanding the regulatory and validation landscape

It is a well-noted fact that the Medical market can be a regulatory dilemma. Changing regulations and legislation make for an oddly dynamic and yet rigid landscape. The FDA’s Center for Devices & Radiological Health for some time now has been implementing more stringent processes around medical device approval and clearance through, for example, increasing the requirements of clinical trials. Equally, the time to clear regulatory hurdles is lengthening in the United States, in some cases presenting to OEMs the reality of introducing products abroad first where time-to-market can be shorter.

This landscape requires plastics manufactures familiar with the idiosyncrasies of the medical market and regulatory regime. The ability to comply with OEM-specific regulations and process controls, frequent OEM audits during manufacturing, full understanding of corrective and preventative action operations, complete quality methodology, process documentation and traceability, are all paramount. For example, does a “new medical” plastics manufacturer understand Class I, Class II, Class IIb, and Class III requirements? Moreover, not only does a manufacturer need to know how to deploy these capabilities, but also, for your benefit when and why, and to guide you in the most cost-effective manner.

The reality is that these characteristics come from a medical products culture. They are not built from nothing easily and over a short period of time. They take years to develop, like any other organic human culture. Spectrum Plastics Group has been in medical for over 50 years and understand this landscape like few other.

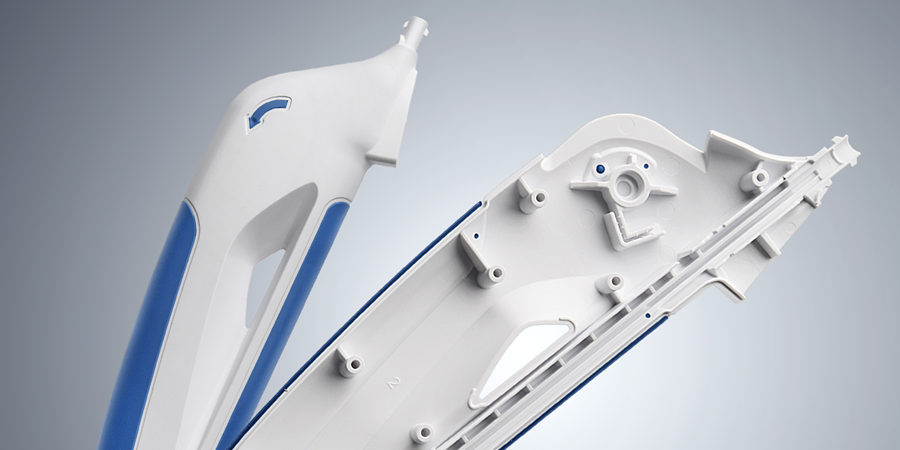

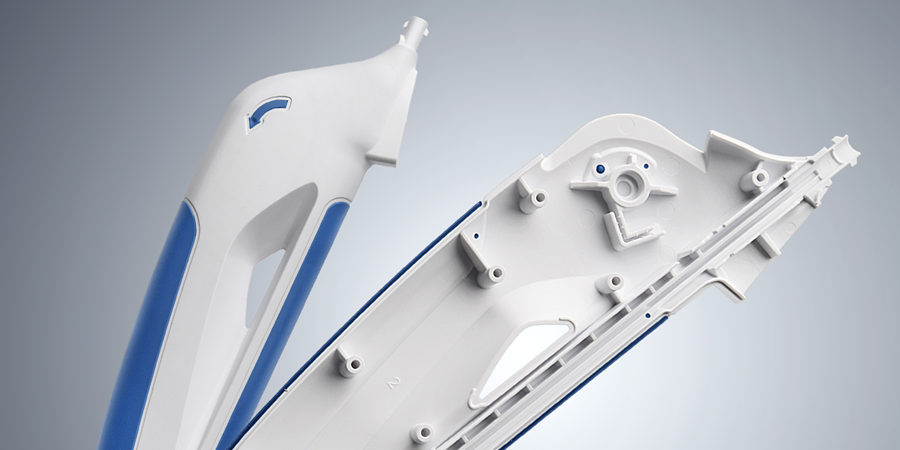

Components only?

Many medical plastics companies these days claim to offer value-added services to the parts or components they manufacture for their customers, whether medical OEMs or their contract manufacturing partners. But do they offer sub-assembly services and clean-room fabrication or packaging? Do they have the ability to not only source adjacent or complementary parts to facilitate an assembly, but also manufacture said parts and manage the controlled environment manufacture from start to finish? Do they bring a larger manufacturing footprint and scale operation to take products to the next level, across geography? The marketplace increasingly needs more than a molder / processor. It needs a stable and trusted medical advisor, partner, assembler, packager, and labeler, among other value-added services.

The truth behind medical clean rooms

It is not uncommon for people when they think of a clean room environment to consider only the particulate count. After all, that is how the designations Class 100,000 (ISO Class 8), and Class 10,000 (ISO Class 7) for example, are framed. But, to be sure, it is far more than this measurement. Temperature and atmospheric controls and elements are also paramount when devices or components are subject to sterilization procedures direct from their cleanroom manufacturing. Particulate count is but one consideration. Without consistent and controlled temperature and humidity, the full and true Bio-burden will not controlled. Hence sterilization validations can be compromised if “dirty” from the perspective of the full Bio-burden and just particulate is taken into account. Be sure to consider your component or contract manufacturer with this in mind when you are vetting plastics manufacturers’ and assemblers’ operations.

Medical people only working on Medical

There are countless companies that cite Medical or Pharmaceutical as one of their key strategic markets. Indeed, a quick query at Plastics News rankings of injection molders cites no less than 200 mentioning medical as a target industry. Many of these businesses may legitimately be so focused on the medical market. But doubtless there are a preponderance that select medical as one of many, and likely have their engineering and quality teams covering a number of market responsibilities. If this is the case, does each have a dedicated medical team working only on medical projects and programs? Or are they partitioned out, with medical being just one of any number of project applications on which they work? Having a focused medical team that speaks and understands medical manufacturing is crucial to being able to provide OEMs the operating culture and support they need.

Medical Materials Development for Medical Applications

The needs of the medical market are ever changing, and fast, as product innovation continues to look to the next horizon. So a question to ask is whether the medical plastics company is but a converter or a true medical partner? And if they are a partner, a good signal would be their ability to innovate in the area of materials technology and materials processing. Experience working with the most advanced materials, such as implantable PEEK, or PLA-based bioresorbables, may underscore not only a company’s commitment to innovation, but also the integrity (and reality) of relationships with material compounders and developers that can help keep it at the forefront of material technology. And a proven track record is a key vendor selection criteria for most OEMs. No one wants to be the guinea pig for a plastics manufacturer. Spectrum Plastics Minnesota, for example, spent years developing its PEEK-processing capabilities as well as its know-how related to all injection molded bioresorbable material grades.

Moreover, does the medical plastics manufacturer feature the necessary and dedicated equipment to product and technical development? Many companies that claim medical may not feature purpose-built processing equipment or space for innovation and development. Rather, they have to meter their time by cutting into production. And we all know how nothing can cut into innovation more than the need to pay today’s bills.

Conclusion

In a plastics manufacturing market that is ever-changing, the medical industry often stands alone in how it rewards or commands simultaneously both dynamism and innovation as well as established and proven processes and regulations. Finding a company that has the experience to navigate these divergent waters can make all the difference for an OEM or other Tier 1 contractor to the industry searching for a medical plastics injection molding partner.