The Effect of Crystallinity on PEEK Performance in Extrusions

There are many semi-crystalline polymers used in medical device applications today, but PEEK (Polyether ether ketone) is fairly unique among them for two main reasons. First, it can be extruded by a variety of methods that can produce either amorphous or fully crystalline tubing, and second, every single one of PEEK’s performance test values are affected by its crystallinity levels. In most cases, it requires specialized in-line processing or secondary operations to achieve fully crystalline PEEK parts. Spectrum Plastics performed a study to quantify the performance differences not only between amorphous and fully crystalline PEEK tubing but also between different methods of tubing crystallization. In this article, we will describe the values tested and the results of these tests below.

There were a few reasons why doing this test is important and should be shared with engineers and consumers alike. First, it is not explicitly clear on easily available documents what the default state of a PEEK part should be, amorphous or crystallized, or that it can even be either one. The material data sheets for PEEK grades from the major manufacturers all mention the semi-crystalline chemistry of PEEK but none state what the samples are for the tests. This ambiguity is not helpful. It is not until one digs into more detailed material information that it becomes clear that the preferred state of PEEK parts is fully crystallized. Moreover, the effect on performance of the crystallinity level often goes unmentioned.

Second, because this information is either lacking or unclear, engineers and consumers may not understand that there is a difference, PEEK parts can be made amorphous or fully crystalline, or somewhere in between, and therefore processors may not go through the extra effort to provide a fully crystalline part. Ultimately, the impact of this ignorance is that the end-user unknowingly receives a part that will not perform to the level that is required and expected.

Finally, the result of all of the above may be to yield failures in the field, something each and every one of us in the medical device industry wishes to avoid. I hope that the information provided here will help end-users in specifying extruded PEEK components as well as aid them in the selection of extruders that are experienced with PEEK and can deliver optimized parts.

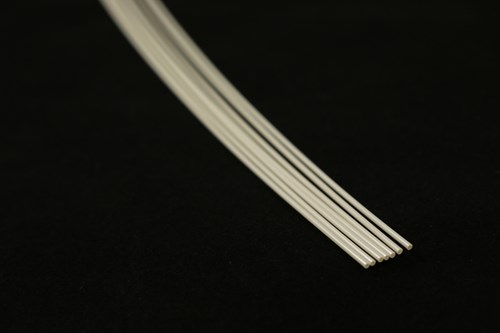

For this test we extruded two sets of tubing, one set amorphous and one set crystallized in-line. We then took some of the amorphous tubes and annealed/crystallized them post extrusion in an oven, which is a common method to achieve full crystallinity in PEEK parts. All extruded tubing was manufactured on the same day on the same extrusion line using the same tooling. The tube size was 0.060” OD x 0.050” ID and was manufactured using recommended processing temperatures and raw material preparation were used for this test. The secondary annealing step was done in an oven.

There are many property values that are contained in material data sheets, but we did not test for all of them for simplicity sake. The properties we did test for--tensile, elongation, flexural and crystallinity-- represent most of the performance characteristics that end-users are mainly concerned with. As we stated earlier, the crystallinity levels of PEEK tubing affect all performance characteristics, including the ones we did not test for, such as electrical, chemical, thermal, density, compression and coefficient of friction.

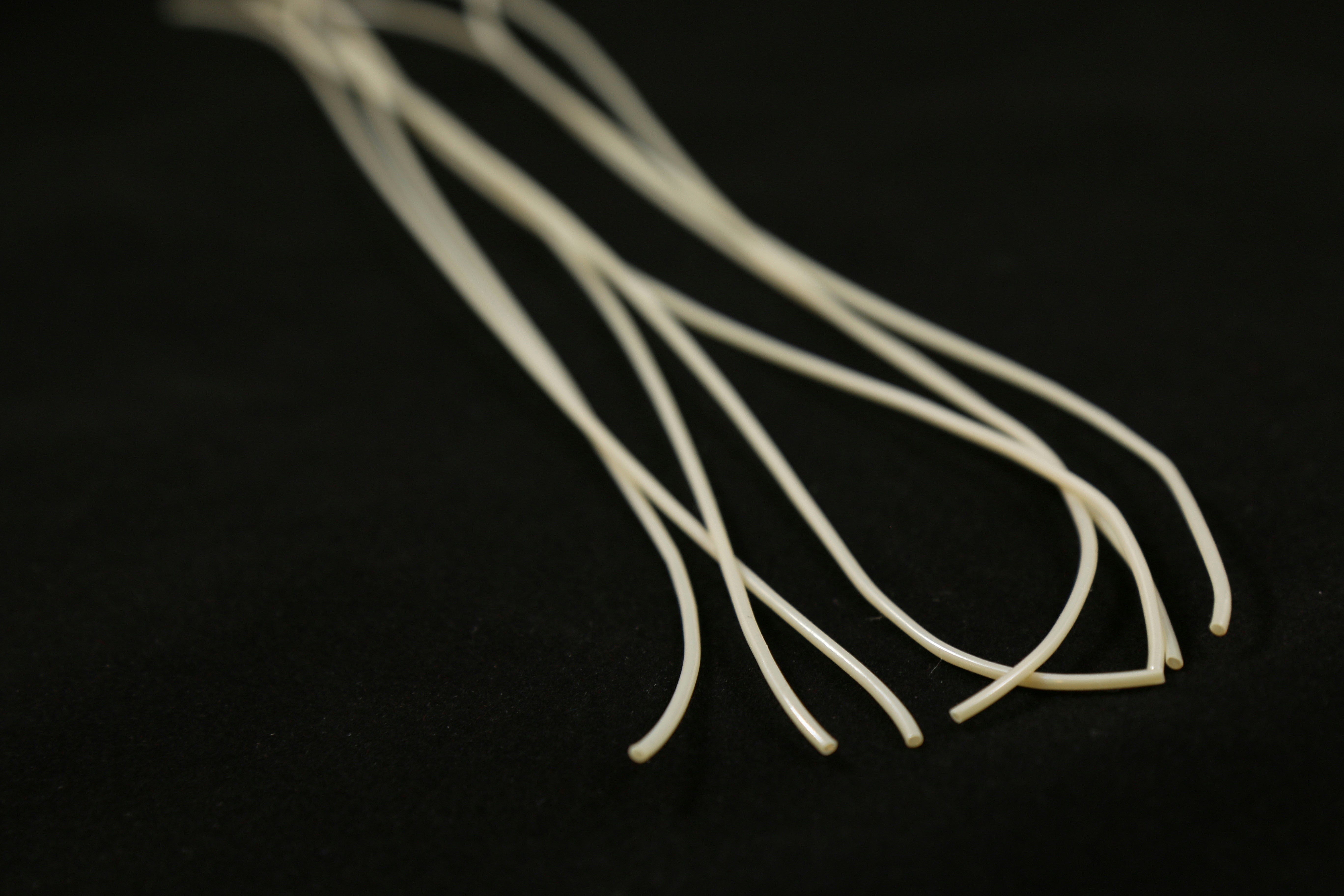

Image: In-line Crystallized PEEK Tubing

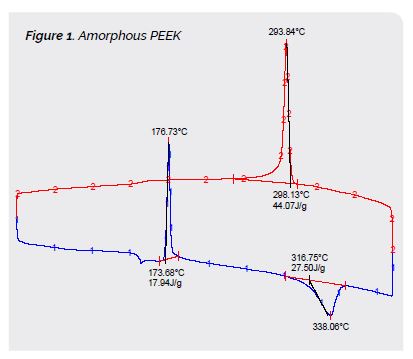

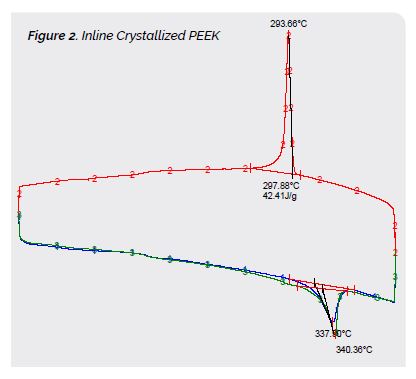

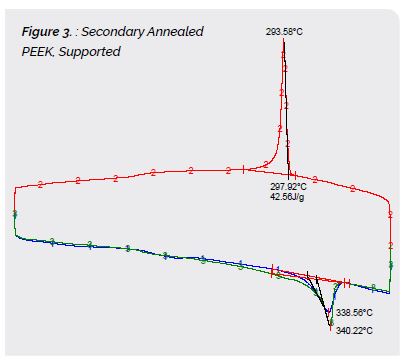

We can see that neither of them shows the peak at about 175° C that the amorphous tubing shows and that they are essentially identical. This tells us that both samples are fully crystallized and that both crystallization methods can make fully crystalline parts. Additionally, these two graphs show that there is no significant heat flow activity until the 340° C melting point is approached, which is why PEEK is known for such high heat resistance. A differential scanning calorimetry (DSC) test was done on all samples to determine the crystallinity levels of the samples. The DSC graph for the amorphous tubing can be seen in Figure 1. The peak at 176.76° C indicates that the sample was not crystalline and that there was a lot of heat flow activity in the samples at this temperature. This is also the temperature range of PEEK’s Tg and HDT. In Figures 2 & 3 are the DSC graphs for the in-line crystallized samples and the secondary annealed samples.

All the heat flow activity that is shown at the 175° C mark on the amorphous samples highlights a very big issue with amorphous PEEK. Crystallinity is achieved by the PEEK molecules moving and aligning and forming crystals when the polymer is soft enough for the molecules to move. This molecular movement after the part has been formed causes the shape and dimensions to change, and when not properly annealed there can be irregular deformation and movement of the parts as seen below in Figure 4 (see right). This represents a potential mode of failure for PEEK parts that are not fully crystalline. Higher heat sterilization methods that are well within PEEK annealing temperatures as well as heat from tool friction and electro-cautery can produce enough heat to release these internal stresses and uncontrollably anneal parts. Aggressive cleaning chemicals and harsh drugs can also release these internal stresses and cause stress cracking. These are some reasons why fully crystallized PEEK extrusions are so important.

Figure 4: Secondary (Improperly) Annealed PEEK

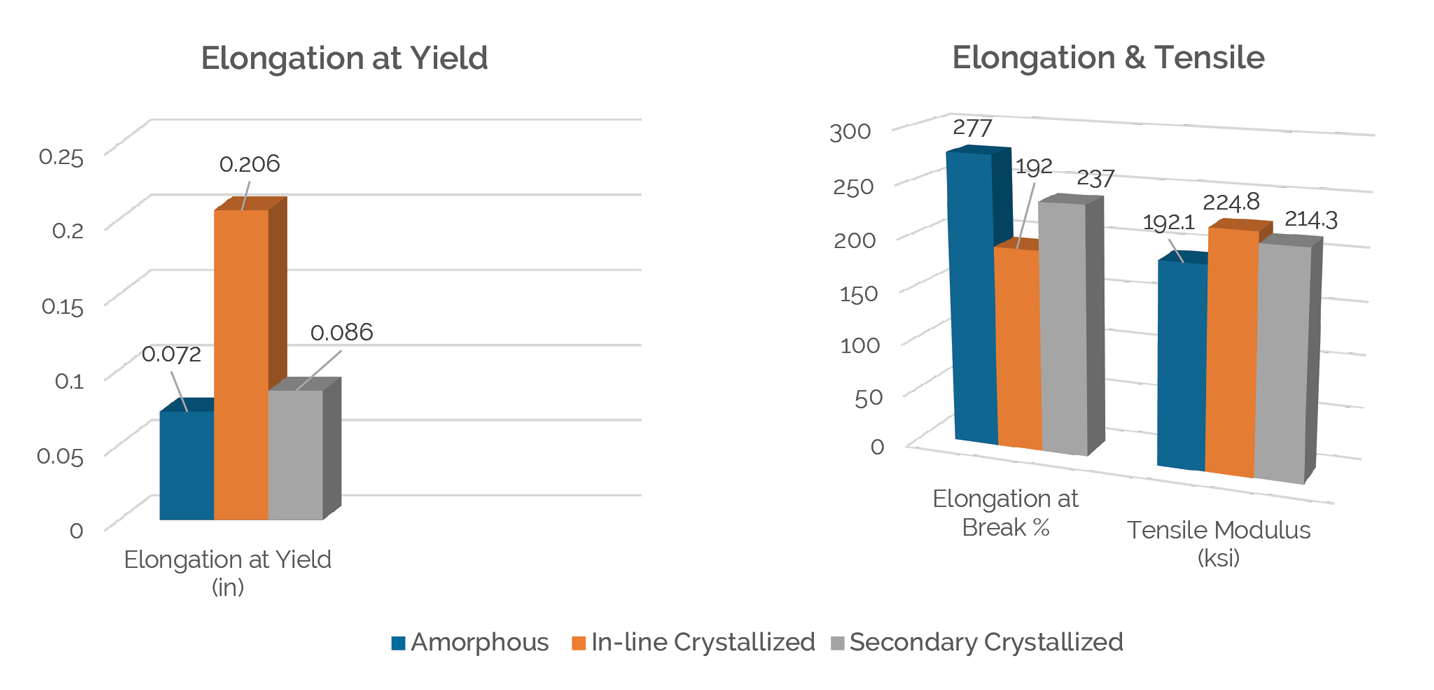

Tensile and elongation properties were tested on these samples and we provided values that correlated to the values typically found on material data sheets. In the Elongation and Tensile chart, elongation at break percentage was lowest for the in-line crystallized sample and highest for amorphous. Amorphous PEEK is more ductile allowing for more stretching before failure, and crystalline samples do not allow as much stretching. The tensile modulus correlates to elongation values in that higher tensile modulus leads to lower elongation in the in-line crystallized samples and the high elongation of amorphous PEEK leads to lower tensile modulus. In the Elongation at yield chart we found some very interesting information that points to situations where elongation at yield performance is critical: in-line crystallized samples have more than twice the performance of the secondary crystallized samples. Additionally, the amorphous and secondary crystallized values are very similar suggesting that crystallinity by itself is not affecting the performance, but rather the crystallization method. A possible explanation for this difference is that the molecules are already aligned in the direction of flow for all extrusions, so all PEEK extrusions, amorphous and crystalline, will have this same level of alignment at their base. The difference with the in-line crystallization process is that the crystals will also be aligned in the direction of flow because they are being formed during the extrusion process and while the material is being drawn down. Crystals that form during the secondary annealing process could be more random and multi directional, which may be beneficial in some applications but has a negative effect on tensile properties.

Flexural properties were also tested, maximum flexural load and flexural modulus. As expected, both types of crystalline samples had higher flexural values than the amorphous sample. The flexural properties for in-line and secondary crystallized samples showed no significant difference in performance. Whatever molecular change or alignment that resulted in higher tensile performance for the in-line crystallized tubing had essentially no impact on flexural properties. Overall, this does show a consistent performance advantage of fully crystallized PEEK parts over amorphous parts in regards to flexural performance.

In conclusion, the objective of this study was to determine whether a condition of full crystallinity be the default state for all PEEK extrusions. The data and test results answer that resoundingly in the affirmative. The data and test results demonstrate that fully crystallized PEEK extrusions will have higher heat stability, increased tensile properties, and increased flexural properties. Consequently, the performance characteristics will yield their “peak” and will match the levels stated on manufacturer-supplied literature and provide more predictable performance for all end use applications.

Many process variables play into what is required for an extrusion to be fully crystallized: size, geometry, line speed, etc. As mentioned, manufacturer literature tends to be somewhat ambiguous regarding the default state of PEEK material and offers little insight into how to achieve full crystallinity with the extrusion process. In order to receive the most consistent, highest performing PEEK extrusions, the processor must be able to understand this concept of crystallinity, how the molecules function and how to interpret all the project variables while transferring this knowhow into a process that will yield the best possible extrusion for the application. Being armed with and aware of these insights permits end-users that need PEEK extrusions to find a processor that will be able to best meet these needs.