Lasers and Extruded Tubing

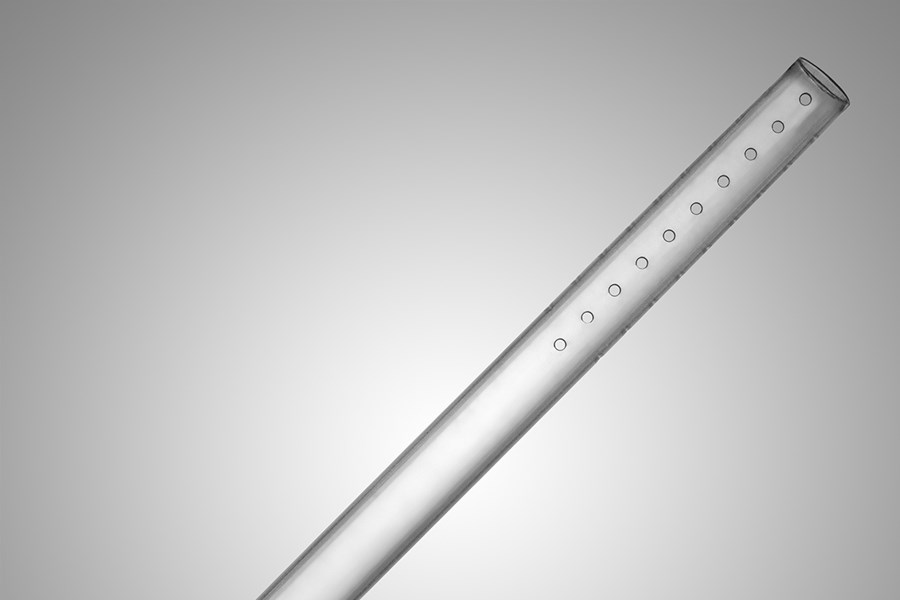

Lasers are high-precision machining instruments that cut micron-scale features in extruded tubing that enable specific medical applications, such as intravascular drug or stent delivery.

Extruded tubing is a commonly used component in medical devices. It is manufactured from a variety of materials and in a wide range of shapes and sizes. Important chemical and physical properties include heat and chemical resistance, lubricity, flexibility, kink resistance, and drug-eluting capabilities. Laser micromachining is a high-precision process that can make a variety of micron-sized features that enhance the functionality of our tubing offerings. In fact, lasers can cut complex features in tubing that cannot be made with any other process.

High-precision laser methods that are frequently used for medical tubing include:

Medical applications for laser-machined extruded tubing include:

Our “off-the-shelf “extruded tubing with laser-cut hole configurations for various medical applications is available via Spectrum Plastics Group’s web store (webstore.spectrumplastics.com) and includes: